Syringe-Pump-Demo

BioFab21_CHBE 3890-02

Project maintained by muszynn Hosted on GitHub Pages — Theme by mattgraham

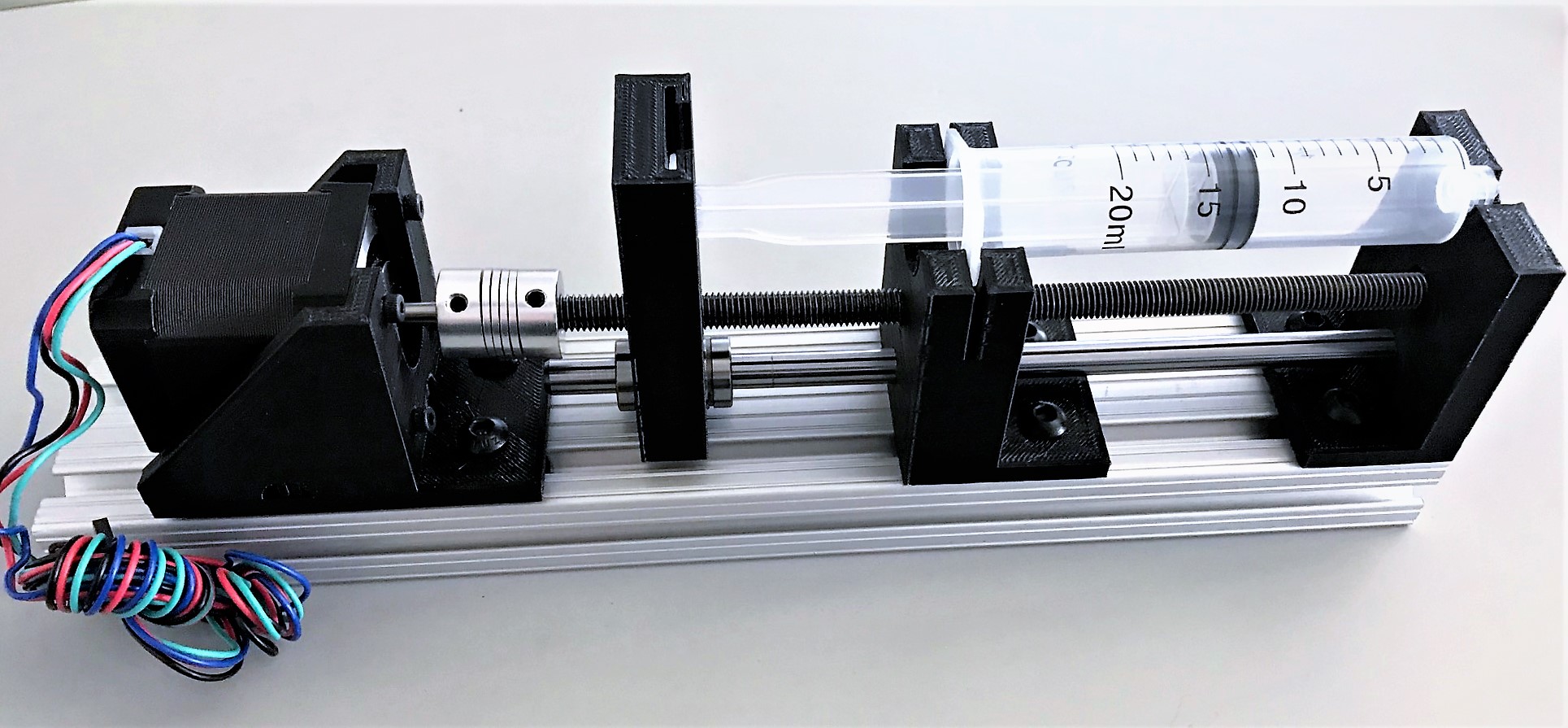

How to Build a Syringe Pump

Overview

Syringe pumps are used in biomedical and chemical scientific research to withdraw or infuse precise but gradual amounts of fluid, with or without added factors such as cells. However, laboratory syringe pumps can run between $500-2000 USD, and building one is much cheaper and easier than one might expect. This website shows you how to model 3D printed parts in Fusion 360, assemble them with commercial products purchased from McMaster Carr, and power the assembled products with an Arduino Uno.

See Mechanical Page here

See Electrical Page here

See Arduino G-code Firmware here

See Flow Rate Specs here

Limiting Factors

The biggest limiting factor of the system sits heavily on the Arduino Uno microcontroller. With embedded systems comes processing speeds much less than your typical desktop. The Arduino Uno runs at a clock speed of 16 MHz and only 2 KB of SRAM (static random access memory). What this means is that the microcontroller can execute up to 16 million commands per second. However, clock cycles are shared between all communications in the system. Since you can only run so many step commands per second, CPU cycles and memory optimization are crucial. This optimization is achieved in the calls of the code, especially surrounding the validations, safety checks, and serial comms. If you are struggling to optimize your code and out of memory, you can always switch to the Arduino Mega. While it also runs at a 16 MHz clock speed, the SRAM is significantly increased to 8 KB.